Water Temperature Control Units

MATIC Water 90 18 E

Product Code: MATIC Water 90 18 E

The MATIC Water 90 18 E temperature control unit offers exceptional precision and efficiency, making it a standout choice for injection moulding applications. Designed to operate with water up to 90°C, it incorporates Tool-Temp's advanced IRIS control system, which ensures intelligent temperature regulation and consistent performance. The compact design of the MATIC Water 90 18 E allows for easy integration into space-constrained environments, while its energy-efficient operation helps reduce overall operational costs. With its reliable and accurate control, this unit is ideal for manufacturers seeking to maintain high-quality moulding results while optimising energy use. Its combination of smart technology, energy savings, and a small footprint makes it the perfect solution for demanding moulding processes.

| Cooling (plate heat exchanger) kW | 130 |

|---|---|

| Cooling (tubular heat exchanger) kW | 50 |

| Heating power (water) kW | 18 |

| Max. temperature (water) °C | 90 |

| Medium | Water (non-pressurised) |

| Pump pressure bar | 4 |

| Range | MATIC |

| Tank capacity L | 20 |

| Unit Type | Temperature Control Units |

- IRIS control system

- Pt100 temperature sensors in feed and return lines

- Heater control by solid-state relays

- Variable-speed pump with automatic eco-mode

- Display of the system and flow pressure

- Automatic water filling

- Mould drainage

- Automatic air venting

- Leakstopper device

- Submersible pump made of tin bronze

- Powerful cooling system: spiral and plate heat exchanger

- Scale-free heat exchanger

- Fully immersed heating elements made of a corrosion-free high-temperature nickel alloy (Incoloy 800)

- Maintenance-free flow meter

- Fixed s

- Pump motor monitored by the variable frequency drive

- Configurable safeguard limits and corresponding reactions

- Configurable audible alarm

IRIS

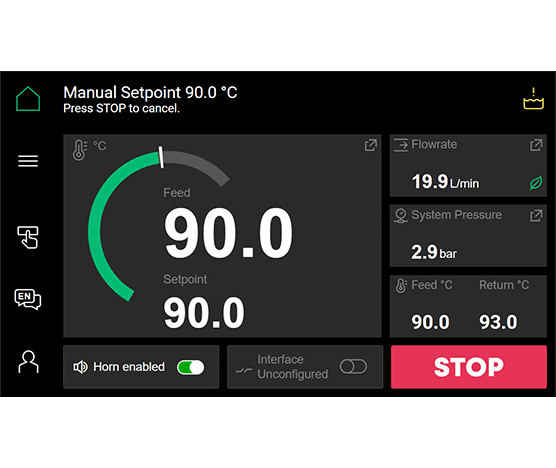

IRIS Control System

With the brand-new control system IRIS, Tool-Temp offers a clever and intelligent solution for all applications in process temperature control. Users can look forward to effortless operation as well as a future-oriented communication and interface solution.

All relevant operating data such as temperatures, pressures, flow rates, operating states, status messages, chart data, and data trends are available in the device. IRIS continuously provides information, reporting, and optimisation of the temperature control unit.

In addition to operation via the touchscreen on-site, remote control is also possible. With any device such as a smartphone, tablet, or PC, access to the integrated web server of the temperature controller can be made via a web browser. The connection is either via a LAN cable or the integrated WLAN adapter in the controller. The operation does not differ in any way from manual control.

The model-based algorithms continuously capture all available data and compare it with the current expected behavior. This continuous adaptation enables the overall system to achieve optimal, uninterrupted, and reliable regulation of temperature and flow, as well as reliable process monitoring.

More InformationDownload Resources

Interested in this product?

Contact our team for more information, pricing, or to discuss your specific requirements.